Our Legacy as a Premier Dealer

Partnering with a Leader in Vinyl Windows & Doors

As an authorized dealer for a company recognized across North America for design excellence, precision craftsmanship, and state-of-the-art technology, we bring you vinyl windows and doors that embody quality and innovation. Our partner’s 50,000 sq. ft. production facility in North York (Toronto) Canada is a testament to their commitment to delivering superior products, and we’re proud to share that legacy with our customers.

Unmatched Craftsmanship

Cutting-Edge Technology for Superior Performance

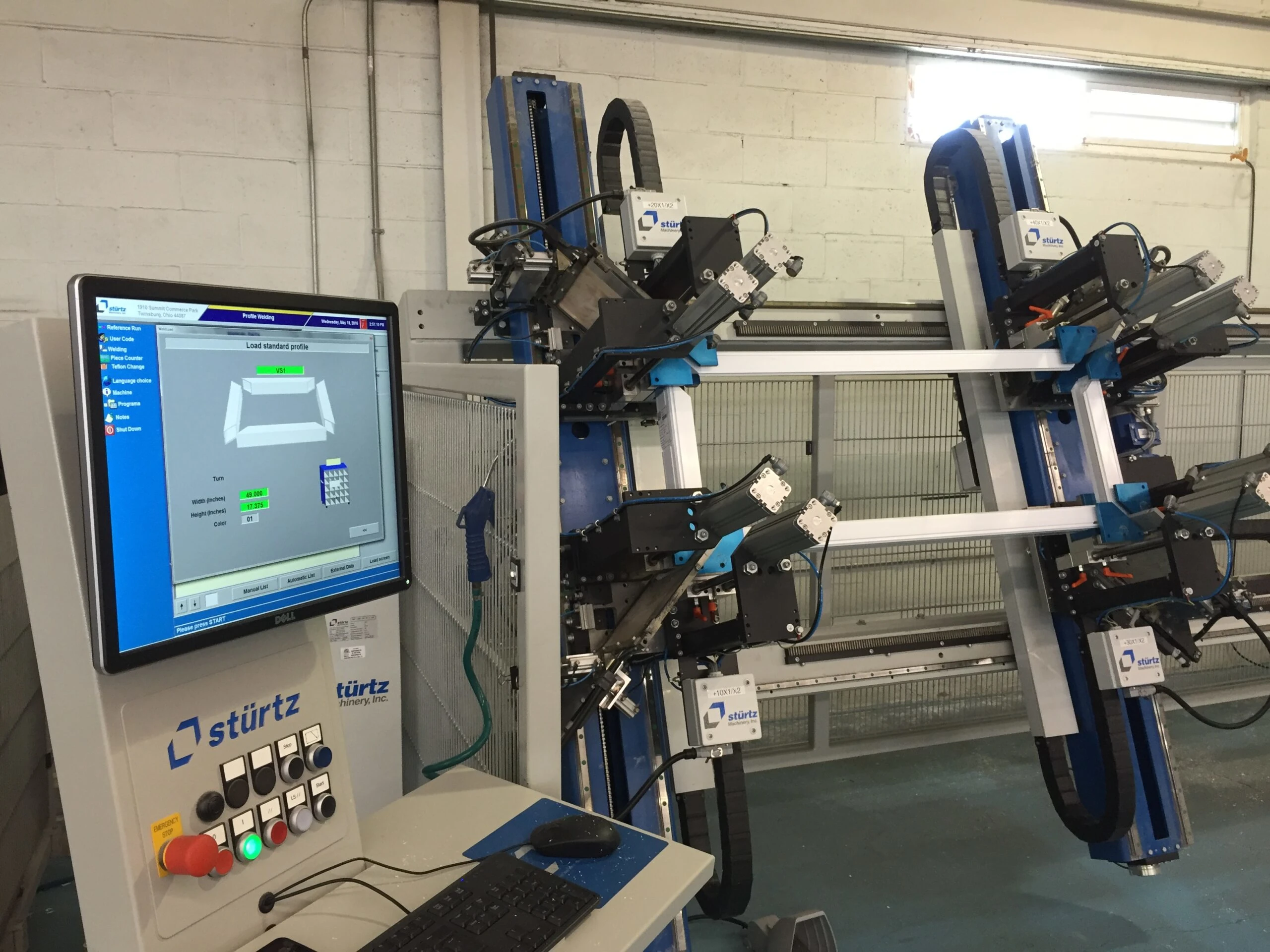

Our partner utilizes the German-engineered Stürtz 4-point fusion welder, the industry leader in vinyl window production. This advanced welding technology simultaneously fusion-welds sash and frame, creating a monolithic box for a perfect fit. The result? Seamless, energy-efficient windows that maintain their integrity for a lifetime, ensuring your home stays comfortable and efficient.

Understanding Stürtz Technology

Stürtz technology refers to the advanced machinery and systems developed by Stürtz Maschinenbau GmbH, a German company recognized as a global leader in providing full-system solutions for vinyl window and door production. Their equipment, particularly the 4-point fusion welder, is designed to deliver precision, efficiency, and durability in the manufacturing of vinyl window and door frames.

Applications in Vinyl Window and Door Manufacturing

Stürtz technology is tailored for vinyl (PVC) window and door production, where precision welding is critical for performance. The 4-point fusion welder is particularly valued for:

- Creating frames and sashes that withstand environmental factors like temperature changes and humidity.

- Supporting complex designs while maintaining structural integrity.

- Enabling manufacturers to meet strict energy efficiency and building code standards.

Precision in Every Pane

Italian-Made Forel “High Tech” IG Line

We deliver windows crafted with precision using the Italian-made Forel “High Tech” IG line, designed for producing double and triple insulating glass units. The process begins with a vertical washing machine featuring four specialized zones—pre-washing, washing, flushing, and drying—equipped with sensors to adapt to glass thickness and Low-E coatings. After washing, the glass moves to an inspection and frame positioning station with LED lighting and movable sliding bars, ensuring flawless quality for both residential and commercial applications.

Understanding Forel Technology

Forel is an Italian company renowned for its advanced machinery and equipment designed for the production of insulating glass units (IGUs), particularly for double and triple glazing used in windows and doors. Their “High Tech” IG line, often utilized by manufacturers of vinyl windows and doors, is a state-of-the-art solution that ensures precision, quality, and efficiency in glass processing for residential and commercial applications.

Applications in Window and Door Manufacturing

Forel’s “High Tech” IG line is specifically engineered for producing insulating glass units used in vinyl windows and doors. Its key contributions include:

- Energy Efficiency: The precise manufacturing process ensures airtight seals, which enhance the thermal performance of windows and doors, reducing energy costs for homeowners.

- Durability: High-quality glass units are resistant to environmental factors like temperature fluctuations and humidity, ensuring long-term performance.

- Versatility: The system supports both residential and commercial applications, accommodating a range of glass types and sizes for customized window and door designs.

Customer-Centric Excellence

Your Trusted Partner for Quality and Innovation

Our dedication to quality extends beyond products to our commitment to you. As a dealer for a brand renowned for its customer-focused approach, we strive to provide exceptional service, ensuring every window and door we offer meets your needs for style, durability, and energy efficiency. Together, we’re building a legacy of trust, craftsmanship, and innovation.